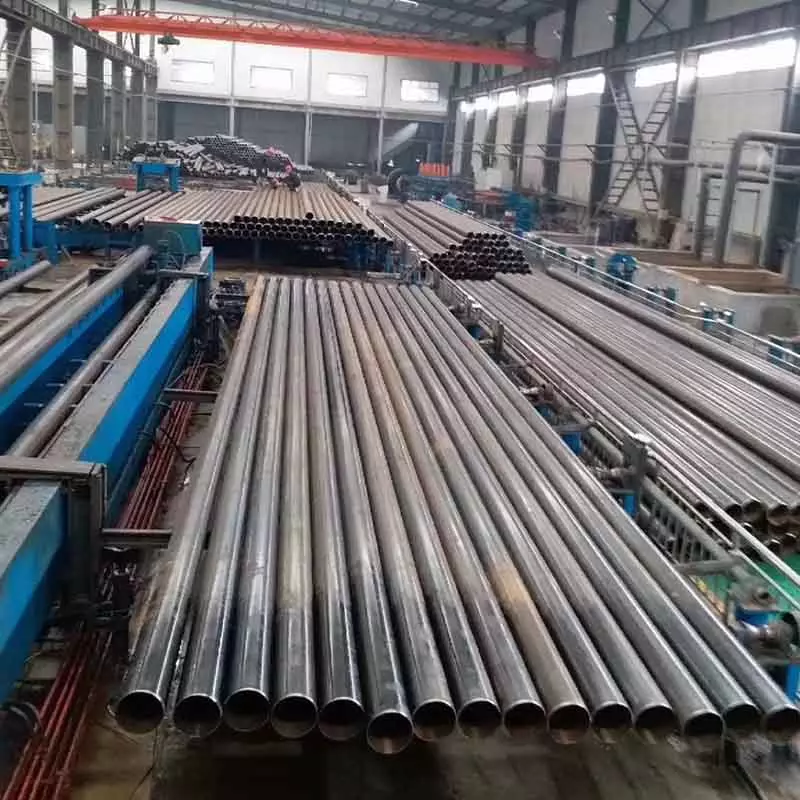

ERW pipes (Electric resistance welded) are construct from steel coil with a parallel weld seam. There is a limit to the diameter of the coil since its width matches the circumference of the pipe.

ERW pipes are manufacture by combining low-frequency and high-frequency resistance. However It is a round pipe made of steel plates that are longitudinally welded. Transporting oil, natural gas, and other vapor-liquid objects is possible with this device. It can handle high and low pressures.

Benefits of ERW GP Pipe and Tubes

•Due to the seam being the only part that needs welding, the rest of the ERW pipe are clean. Therefore, cleaning, grinding, and trimming welded pipe and tube end is usually all that must be done post-wedding.

•A higher strip rolling accuracy and tighter control of pipe material give ERW pipe an advantage over seamless pipe regarding dimensional accuracy.

•Tubes and ERW pipes made by ERW are highly impact-resistant.

•ERW pipe pre-galvanized with zinc have strong corrosion and rust resistance.

•Since pipes and tubes are make from steel sheets of uniform thickness, their micro structure is uniform.

Faqs:

What is the use of erw pipes?

The strength and corrosion resistance of ERW Pipes make them ideal for buildings in mountainous and coastal regions. As a result, roofing structures are being construct with them in place of wood. With this ASTM A213, and Astm A335 are also the two best options of pipes.